- New HPM-400 electric motor has peak power of 400kW, peak torque of 250Nm yet weighs just 40kg overall with an integrated silicon carbide (SiC) inverter

- High power, short duration motor originally designed as a high-performance fuel pump for Gilmour Space Technologies’ Eris rocket programme

- HPM-400 can operate at atmospheric pressure and in a vacuum – and as well as for space applications, is also ideal for the aerospace and marine sectors

- Engineered and manufactured in the UK at Equipmake’s Snetterton facility, technology born out of Equipmake’s experience in F1 and top-level motorsport

- Visit Equipmake at the Future Propulsion Conference, Solihull

- Hi-res images: https://bit.ly/Equipmake_HPM-400

1st March 2023: Leading electrification specialist, Equipmake, has today unveiled an ultra-lightweight, power-dense electric motor, designed for high-performance space, aerospace, and marine applications.

Debuted at the Future Propulsion Conference, held in Solihull, UK, the HPM-400 is an advanced high power, short duration motor that was original specified as a high-performance rocket fuel pump for Australian company, Gilmour Space Technologies, for use in its Eris rocket programme.

Featuring several technological and packaging innovations born out of its need to withstand extreme acceleration while also operating at atmospheric pressure and in space, the HPM-400 has multiple applications in high-performance environments.

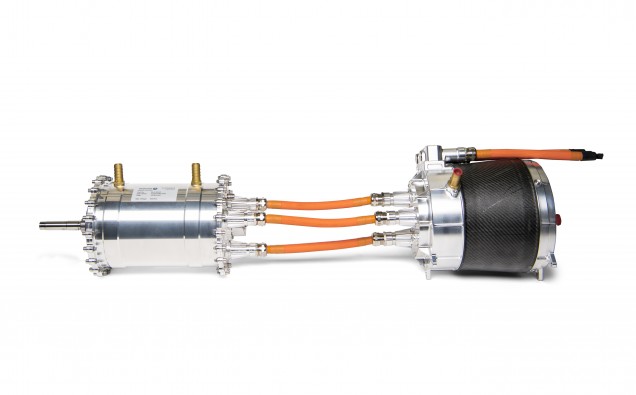

With a maximum motor speed of 20,000rpm, peak power/torque of 400kW/250Nm, yet a mass of just 30kg for the motor only, the HPM-400 is believed to be the most power dense in the world. Combined with its integrated silicon carbide inverter, which weighs only 10kg, the entire system tips the scales at just 40kg.

Ian Foley, CEO, Equipmake, said: “Because of its original intention for use as a rocket fuel pump, the HPM-400 features several novel innovations over conventional motor/inverters, making it ideal for use in high-performance space, aerospace and marine applications.

“Firstly, the complete package is ultra-lightweight and capable of withstanding incredible acceleration. Secondly, when an inverter must operate in a vacuum, it needs to be high voltage, because lots of power is required.

“HPM-400 keeps air pressure inside and has been completely redesigned mechanically to withstand the pressure from within when it goes from atmosphere into a vacuum. That has resulted in a super compact cylindrical package – conventional inverters being square – with a carbon fibre shell to keep pressure in and weight down. It all adds up to an advanced high power, low weight motor/inverter that’s at home in space, air or water.”

Based in Snetterton, Norfolk, Equipmake provides the complete electric mobility solution – whatever the sector – offering the capability to design, test and manufacture everything from motors to fully electrified platforms.